FCT COMBUSTION NEWSLETTER: October 2021

Dear Friends,

I hope this newsletter finds you well. For almost 2 years now, the world has been turned upside down in a state of uncertainty, as the COVID-19 pandemic affected people across the world, and I sincerely hope that you and your loved ones have remained safe throughout the pandemic.

This is my first newsletter as FCT Group CEO. I would first like to thank Con Manias for his hard work and leadership in building FCT to this point, where we are a market leader and proven choice for complete combustion solutions worldwide. I am pleased to take on this new leadership role and expanding on Con’s good work into the future, together with the support of the FCT family.

As a team, we are focused on developing a company with emphasis on understanding the needs of our customers and of the broader market, and we are articulating our new products road map with a converged focus on advanced pyro-processing technologies respecting the environment and offering the best available service the industry can find.

Over the past year, this has consisted of an expansion of our Low NOx range of products for iron ore pellets and hot gas generators, with products to suit both traditional and alternative fuel types, as well as the introduction of our clay calcining technologies for high quality production of green cement.

We have also entered various research partnerships, most recently including the HILT (Heavy Industry Low-carbon Transition) CRC alongside other partners including the University of Adelaide, ADBRI, Primetals, Calix, Alcoa, Fortescue, CSIRO, Worley, and more. In Europe, we are also delivering a hot gas generator with accessories and control system as part of the expansion of the EU H2020 Leilac (Low Emissions Intensity Lime & Cement) Pilot for CO2 emission reduction.

More recently, we have also been concentrating efforts on hydrogen as an emerging industrial fuel source to meet the environmental goals of our clients. Already, we have successfully installed our I-Jet burners with substitution at some iron ore pelletizing plants. Our in-house R&D facility continues to develop and test burners using this and other emerging fuel sources.

These are just some of the initiatives we are involved in to ensure our customers enjoy access to the best technologies, with peace of mind that we are committed to helping you achieve your goals – whether that be improved efficiency, increased product quality, reduced fuel costs, decreased emissions, and other environmental objectives, or all the above.

Throughout the pandemic, we have been lucky. We are well positioned with a network of international offices, as well as work-from-home arrangements, so that we have had minimal interruptions to our operations. We have had the ongoing support of our valued customers and associates and strive to repay this every day with a strong commitment to delivering the best products, service, and support.

Coming to the end of 2021, the world is starting to look toward the future with many countries planning ways to safely reduce restrictions through the introduction of new protocols and increased vaccine availability. We are excited to see our friends, clients, and other associates again when it is safe to do so.

In the meantime, I hope you will enjoy our newsletter and as always, please feel free to contact us via our website contact page or following us on LinkedIn

Wishing you all the best,

Adriano Greco

FCT Group CEO

PROJECTS ACROSS THE GLOBE

RECENTLY COMPLETED OR CURRENTLY ACTIVE PROJECTS ACROSS FCT COMBUSTION INCLUDE:

AUSTRALIA: BHP Olympic Dam

FCT is delivering an oxy-fuel burner package for BHP’s flash smelting furnace at Olympic Dam in South Australia. The upgrade will extend the life of the furnace, reducing waste and reducing emissions associated with manufacture. In addition to the custom burners for both the North and East walls of the Settler Bath, accompanying burner management systems, valve trains, oxygen analysers and ancillaries are also included within the scope.

AUSTRALIA: Mine to Map

FCT is testing feed material to determine which FCT calcined clay technology would be of most benefit for the feed material’s unique characteristics. As a supplier of both types of calcined clay technologies – FlashCalx flash calciner and RotaCalx rotary calcining solution, FCT is an unbiased partner when determining which is the most suitable calcining approach for a given material.

AUSTRALIA: SIMEC Mining, Whyalla

FCT is conducting a CFD Study as part of the modernisation of the Whyalla Steelworks green steel plant. The CFD study follows a prefeasibility study conducted by FCT regarding the conversion of a grate-kiln burner from coke oven gas to 100% natural gas, as well as investigating the possibility of using hydrogen as a clean alternative fuel in the plant.

AUSTRALIA: Graymont, New South Wales

FCT is delivering a new burner system in support of Graymont’s restart of its lime plant in Charbon, New South Wales.

AUSTRALIA: Albermarle, Kemerton

FCT is supplying the combustion system and gas analyser to Metso:Outotec’s lithium plant in Kemerton, WA. The project will be commissioned later this year.

BRAZIL: Vale, Vitoria

FCT has been awarded a contract to supply a set of 90 burners for Vale’s iron ore pelletizing plant in Vitoria. The scope also included valve trains, flame sensors, igniters, gas analysers, flow meters and various other equipment to convert the kilns to natural gas and improve operational safety.

Burners and valve trains being manufactured for Vale in Brazil

BRAZIL: Vale, Vitoria

As a continuation of the natural gas conversion and operational safety upgrade of Vitoria’s plant, FCT has been awarded a contract to supply a set of 106 burners for Kilns 5, 6, and 7 to the iron ore pelletizing plant in Vitoria. The scope also includes the necessary valve trains, flame sensors, igniters, gas analyses, flow meters, and various other components.

BRAZIL: Icon Máquinas, Criciuma

FCT has been awarded the contract to supply 3 new hot gas generators to Icon Máquinas in Criciuma, for which the final customer is Vale’s New Steel project. Two of the natural gas fired Hot Gas Generators will be installed in the Vitoria plant, and the third Multi-Fuel equipment will be installed in Vargem Grande, MG. All Hot Gas Generators will be supplied in partnership with Icon, who will integrate the equipment to their dryers.

BELGIUM: Cimenterie CBR, Lixhe

FCT recently delivered a hot gas generator with accessories and control system. The hot gas will be used to preheat raw material as part of an expansion of the EU H2020 Leilac (Low Emissions Intensity Lime & Cement) Pilot for CO2 emission reduction.

Hot gas generator for Cimenterie CBR, Lixhe, Belgium.

CANADA: Undisclosed client

FCT has been awarded the contract to supply a new hot gas generator in Canada. The supply comprises the complete hot gas generator including the burner, valve train, igniter system and the components to safely operate the system. The new HGG will combust natural gas to generate hot gases at controlled temperatures to supply thermal energy to a rotary dryer.

CAMEROON: Undisclosed client

FCT has recently delivered a complete fuel oil system for a calciner and a hot gas generator, from truck unloading pumps to valve trains inlet. The scope includes tanks, filtering, pumping and heating stations. Commissioning is expected for 2022.

GERMANY: HeidelbergCement

FCT has recently delivered a Turbu-Flex™ burner for HeidelbergCement’s Burglengenfeld plant. The targets of the project are to maximise the use of alternative fuels as well as to improve combustion control. Commissioning is expected for early 2022.

Turbu-Flex™ burner for HeidelbergCement’s Burglengenfeld plant in Germany

HONG KONG: Green Island Cement

FCT has been awarded a contract to deliver a burner to Green Island Cement, which will increase the plant’s alternative fuel firing capabilities for reduced emissions, alongside coal firing.

JAPAN: Sumitomo Mining & Metals

FCT is supplying a burner to Sumitomo Mining & Metals (SMM) in Japan, for ferro-nickel reduction application. The burner will ensure a high degree of flexibility in heat flux profile to allow for scale-up in the future as the client’s needs change and grow.

NAURU: Republic of Nauru Phosphate Corporation (RONPHOS)

RONPHOS has two rotary kilns for drying phosphate rock, each with its own hot gas generator. FCT is supplying a combustion system including two burners, a spare rotable burner, and associated accessories. The combustion system will be designed to utilise waste oil and diesel. Delivery is expected for June 2021.

OMAN: Vale, Sohar

FCT will supply a Gyro-Therm™ burner for iron ore pelletizing grate-kiln application, to be installed at Vale’s plant in Sohar, Oman.

RUSSIA: Eurocement, Belgorod

FCT has delivered a Gyro-ThermTM burner with accessories for kiln 7 in Belgorodsky cement plant. The main target of the project is to reduce fuel specific consumption. The burners are designed to fire natural gas and solid alternative fuels. Included within the scope are the burner with accessories,, igniters, flame sensors, igniter valve trains, and control systems. Commissioning is expected for late 2021 or early 2022.

Gyro-Therm™ burners were delivered to various Eurocement plants across Russia

RUSSIA: Eurocement, Ust-Dzheguta

FCT has delivered two Gyro-Therm™ burners with accessories for kilns 2 and 4 in Kavkazcement plant. The main target of the project is to reduce fuel specific consumption. The burners are designed to fire natural gas and solid alternative fuels. Included within the scope are the burner with accessories, igniters, flame sensors, igniter valve trains, and control systems. Commissioning is expected for late 2021 or early 2022.

RUSSIA: Eurocement, Fokino

FCT has delivered four Gyro-Therm™ burners with accessories for kilns 8, 9, 10 and 11 in Maltsovsky portlandcement plant. The main target of the project is to reduce fuel specific consumption. The burners are designed to fire natural gas and solid alternative fuels. Included within the scope are the burner with accessories, igniters, flame sensors, igniter valve trains, and control systems. Commissioning is expected for late 2021 or early 2022.

RUSSIA: Eurocement, Nevyanskiy

FCT has delivered a Gyro-Therm™ burner with accessories for kiln 1 in Nevyanskiy cement plant. The main target of the project is to reduce fuel specific consumption. The burners are designed to fire natural gas and solid alternative fuels. Included within the scope are the burner with accessories, igniters, flame sensors, igniter valve trains, and control systems. Commissioning is expected for late 2021 or early 2022.

RUSSIA: Eurocement, Stariy Oskol

FCT has delivered two Gyro-Therm™ burners with accessories for kilns 4 and 5 in Oskolcement plant. The main target of the project is to reduce fuel specific consumption. The burners are designed to fire natural gas and solid alternative fuels. Included within the scope are the burner with accessories, igniters, flame sensors, igniter valve trains, and control systems. Commissioning is expected for late 2021 or early 2022.

RUSSIA: Eurocement, Mikhaylov

FCT has delivered one Gyro-Therm™ burner with accessories for kiln 1 in the Mikhaylov plant. The main target of the project is to reduce specific fuel consumption. The burners are designed to fire natural gas and solid alternative fuels. Included within the scope are the burner with accessories, igniters, flame sensors, igniter valve trains, and control systems. Commissioning is expected for late 2021 or early 2022.

SOUTH AFRICA: Undisclosed client

FCT is conducting a CFD study for the selection of a new burner system to Top Submerged Lance (TSL) Smelter.

TURKEY: Deha Industry, Kayseri

FCT has delivered a burner for a new zinc recuperation kiln in Kayseri, Turkey. the main fuel is natural gas. As part of the complete scope, FCT supplied the burner, natural gas valve train, burner management system, primary air fan, igniter, flame sensor and minor accessories. Commissioning is underway.

USA: Ash Grove Cement, Chanute KS

FCT has been awarded a contract to supply a new multi-fuel burner for the cement kiln in Chanute Plant. The new Turbu-Jet™ burner system will be able to fire up to 100% coal/petcoke, natural gas and 40% liquid waste.

USA: US Silica, Vale OR

FCT has been awarded the contract to supply a safety system upgrade for kiln 1 installed in US Silica’s plant in Oregon. The project aims to update the existing natural gas valve train to comply with the latest NFPA safety requirements, including new ignition system. A new burner management system will also be installed.

UNDISCLOSED COUNTRY/CLIENT

FCT has been awarded a contract to supply a set of 20 natural gas burners for an iron ore pelletizing plant. The scope also includes valve trains, flame sensors, igniters, flow meters, fans, local control boxes and spare parts. Delivery is planned for the beginning of 2022.

PEOPLE OF FCT

At FCT, we know that our continued success is largely due to our team’s commitment to providing the best products, service, and expertise across all our offices. We are pleased to announce the newest additions and changes within our team:

Rodrigo Elisei, Global Business Development Executive, FCT Combustion

We are pleased to announce that Rodrigo Elisei has accepted the position of Global Business Development Executive for Iron and Steel. Rodrigo will oversee global market development and will be based in FCT’s European Office. Rodrigo brings with him 20 years of industry experience, most recently holding the position of Executive Manager at Vale. We are very proud to Welcome Rodrigo to FCT. To read more about this appointment, please click here

Bruno Garcia, Director of Engineering and Projects (Americas)

Bruno joined FCT Combustion in March 2021 as Director of Engineering and Projects. Bruno brings with him a wealth of managerial experience in the sector and across the Americas. He has previously worked at Claudius Peters for almost 20 years, beginning as a Sales Engineer and eventually becoming Managing Director of the Brazilian subsidiary in Sao Paulo before moving into the role of Head of Engineering and Projects at Claudius Peters’ Dallas, TX office. Bruno holds a Bachelor of Mechanical Engineering and specializations in Strategic Negotiations, Finance and International Business.

Diego Bernhard, Engineering Manager, FCT Combustion (Americas)

Diego joined FCT Combustion in January 2020 as a Senior Project Engineer, before ascending to the role of Engineering Manager in January 2021. Diego graduated from the University of Sao Paulo – Escola Politécnica with a Bachelor of Mechanical Engineering and has more than 15 years of industry experience having worked in engineering roles at Greco and at FLUE8 Equipamentos as a Technical Manager. Diego has skills in thermal engineering, environmental engineering and project coordination.

FCT a key partner of HILT CRC

In our September 2020 issue, we announced our commitment to a low carbon research initiative led by the University of Adelaide – Heavy Industry Low-carbon Transition Cooperative Research Centre (HILT CRC). On 30 June 2021, funding was officially announced by the Minister for Industry Science and Technology of Australia.

FCT is proud to be a key partner of the HILT CRC, which will focus ondeveloping technologies and methods that overcome barriers, enabling Australia’s heavy industry sector to compete in the low-carbon global economy for carbon-neutral materials.

The initiative will be Australia’s leading collaboration transforming heavy industry to a low carbon economy. Some of the key industries being addressed in the HILT CRC research are iron and steel, cement, lime, alumina, and other processed minerals. Fuel sources such as hydrogen will also form another major aspect of the planned research.

FCT has industrial experience in the use of hydrogen for iron ore pelletising kilns, with up to 50% fuel substitution. At our in-house R&D facility, based in our Asia-Pacific office, we have been conducting our own research into viably extending the fuel substitution rate to 100%.

The University of Adelaide is in the top 1% of universities in the world and ranked 7thin the world for mining and mineral engineering. FCT Combustion and University of Adelaide have a proud history of collaboration, working on the development and commercialization of low NOx burner technology for more than 30 years. We look forward to providing our continued support and expertise to the university run initiative alongside a group of inspiring researchers, technology companies and end-users.

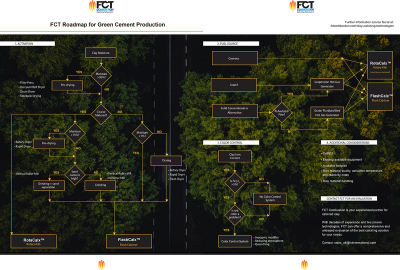

Two popular methods to calcine clay: an evaluation

Over the course of two articles, FCT evaluates the different methods, opportunities, and challenges of producing green cement to realise the best environmental and economic benefits available. Part one of the series ‘A Focus on Flash Calcining’ explores the flash calcining approach, while ‘The Rotary Kiln Approach’ explores the improvements made on traditional rotary kiln technology to successfully adapt to clay calcining.

Please download the articles by clicking below. For more information about the topic of clay calcining, as well as the available technologies and which scenarios they are best suited to, you can also scroll down to view some of our webinars on the topic:

- Producing Green Cement Using FCT Calcined Clay Technologies

- Identifying the best FCT Calcined Clay Technology for different scenarios, using case studies

- FlashCalx Calcined Clay Technology, Case Studies and Color Management Strategies