FCT COMBUSTION NEWSLETTER: JULY 2021

Dear Friends,

There is light at the end of the tunnel with Covid. It is heartening to see the dramatic reduction in new infections in those countries with advanced immunisation programs, and it is a credit to humanity that we have been able to respond to meet the challenges created by the pandemic.

The world is emerging from this shake up into a slightly different norm that we will all have to adapt to. People are more conscious of hygiene and social distancing, greater use of electronic meetings and working from home, less travel, use of tracing apps or systems, perhaps some re-evaluating of personal aspirations etc. It has been a massive 18 months for the world.

For FCT, it has also had a profound effect in the way we operate. We have four main offices in the US, Brazil, Australia and Austria, and have been able to service our customer needs from these. We have in mind further expansion into other countries.

But we have also been able to function well from our homes or our offices to provide remote support for our customers globally – in isolation or not. Our business model has been refined to be able to offer local support to our projects through associates in some countries in the event that we are not able to travel there directly.

Our strategic intent though remains unchanged. We are continuing to grow the company with better geographic spread, with continually growing and improving product lines, by expanding into more industries and by increasing the scope of the projects we take on.

FCT has continued to grow its revenues despite the challenges of Covid, and this newsletter gives some look at the current projects in hand. The value of orders won in May this year has been a record by far – more than double any previous monthly record.

We have a focus on environmentally based technology and are undertaking R&D and product development in related areas including hydrogen fuel technologies, lower NOx technologies and clay calcination for cement use.

We live to provide benefits and value to our customers and the degree of repeat business we enjoy is testament to that.

We are really optimistic with what lies ahead and what we will be able to do into the future.

But there is also change and transition that has been underway at FCT for some time now, and this will be my last newsletter as Managing Director of FCT Holdings.

I am delighted that Adriano Greco will take over this role from June, and I have every confidence that the company will prosper under his leadership. I congratulate Adriano on his success to date and on him accepting the challenge to take the company forward. I have no doubts about the success that will follow.

I will remain as Executive Chairman of the FCT Board.

I thank everyone for the support I have enjoyed, and for all the friendships I have formed during my time as CEO of the FCT Group – and trust that many of these will continue.

Enjoy the Read.

Managing Director

FCT International

*Editor’s note: this letter was written in May 2021. Adriano Greco has since taken over the role of FCT Group CEO, starting from June 1 2021.

PROJECTS ACROSS THE GLOBE

RECENTLY COMPLETED OR CURRENTLY ACTIVE PROJECTS ACROSS FCT COMBUSTION INCLUDE:

AUSTRALIA: BHP Olympic Dam

FCT is supplying a custom designed burner with valve train, burner management system and accessories as part of SCM21.

AUSTRALIA: Mine to Map

FCT is testing feed material to determine which FCT calcined clay technology would be of most benefit for the feed material’s unique characteristics. As a supplier of both types of calcined clay technologies – FlashCalx flash calciner and RotaCalx rotary calcining solution, FCT is an unbiased partner when determining which is the most suitable calcining approach for a given material.

AUSTRALIA: SIMEC Mining, Whyalla

FCT is conducting a CFD Study as part of the modernisation of the Whyalla Steelworks green steel plant. The CFD study follows a prefeasibility study conducted by FCT regarding the conversion of a grate-kiln burner from coke oven gas to 100% natural gas, as well as investigating the possibility of using hydrogen as a clean alternative fuel in the plant.

AUSTRALIA: Graymont, New South Wales

FCT is delivering a new burner system in support of Graymont’s restart of its lime plant in Charbon, New South Wales.

AUSTRALIA: Albermarle, Kemerton

FCT is supplying the combustion system and gas analyses to Metso: Outotec’s lithium plant in Kemerton, WA. The project will be commissioned later this year.

BRAZIL: Vale, Vitoria

FCT has been awarded a contract to supply a set of 90 burners for Vale’s iron ore pelletizing kilns 3 and 4 in Vitoria. The scope also included valve trains, flame sensors, igniters, gas analysers, flow meters and various other equipment to convert the kilns to natural gas and improve operational safety.

BRAZIL: Vale, Vitoria

As a continuation of the natural gas conversion and operational safety upgrade of Vitoria’s Plant, FCT has been awarded a contract to supply a set of 106 burners for Kilns 5, 6 and 7 to the iron ore pelletizing plant in Vitoria. The scope also includes the necessary valve trains, flame sensors, igniters, gas analysers, flow meters and various other components.

BRAZIL: Icon Máquinas, Criciuma

FCT has been awarded the contract to supply 3 new hot gas generators to Icon Máquinas in Criciuma which the final customer is Vale’s New Steel project. Two of the natural gas fired Hot Gas Generators will be installed in Vitória Plant and the third Multi-Fuel equipment will be installed in Vargem Grande, MG. All HGGs will be supplied in partnership with Icon that will integrate the equipment to their dryers.

BELGIUM: Cimenterie CBR, Lixhe

FCT has been awarded a contract to deliver a hot gas generator with accessories and control system. The hot gas will be used to preheat raw material as part of an expansion of the EU H2020 Leilac (low Emissions Intensity Lime & Cement) Pilot for CO2 emission reduction.

CANADA: Undisclosed client

FCT has been awarded the contract to supply a new hot gas generator in Canada. The supply comprises the complete hot gas generator including the burner, valve train, igniter system and the components to safely operate the system. The new HGG will combust natural gas to generate hot gases at controlled temperatures to supply thermal energy to a rotary dryer.

CAMEROON: Undisclosed client

FCT has been awarded a contract to deliver a complete fuel oil system for a calciner and a hot gas generator, from truck unloading pumps to valve trains inlet. The scope includes tanks, filtering, pumping and heating stations. Delivery is scheduled for 2021.

FRANCE: Ciments Calcia, Couvrot

FCT has recently commissioned a Turbu-Flex™ burner for Ciments Calcia’s Couvrot plant. The targets of the project are to maximise the use of alternative fuels, as well as to improve combustion control.

GERMANY: HeidelbergCement

FCT has been awarded a contract to deliver a Turbu-Flex™ burner for HeidelbergCement’s Burglengenfeld plant to be delivered by July 2021. The targets of the project are to maximise the use of alternative fuels as well as to improve combustion control. Commissioning is expected for the second half of 2021.

HONG KONG: Green Island Cement

FCT has been awarded a contract to deliver a burner to Green Island Cement, which will increase the plant’s alternative fuel firing capabilities for reduced emissions, alongside coal firing.

JAPAN: Sumitomo Mining & Metals

FCT is supplying a burner to Sumitomo Mining & Metals (SMM) in Japan, for ferro-nickel reduction application. The burner will ensure a high degree of flexibility in heat flux profile to allow for scale-up in the future as the client’s needs change and grow.

MALAYSIA: WK Asia Pacific

FCT recently supplied a waste liquid valve train for WK Asia Pacific.

NAURU: Republic of Nauru Phosphate Corporation (RONPHOS)

RONPHOS has two rotary kilns for drying phosphate rock, each with its own hot gas generator. FCT is supplying a combustion system including two burners, a spare rotable burner, and associated accessories. The combustion system will be designed to utilise waste oil and diesel. Delivery is expected for June 2021.

OMAN: Vale, Sohar

FCT will supply a Gyro-Therm™ burner for iron ore pelletizing grate-kiln application, to be installed at Vale’s plant in Sohar, Oman.

RUSSIA: Metalloinvest, Lebedinsky Gok (LGOK)

Lebedinsky GOK is the largest plant for the beneficiation of iron ore in Russia and the CIS, producing high quality iron ore and raw materials. FCT Combustion has commissioned 18 I-Jet™ burners, as well as valve trains and Burner Management Systems for the natural gas straight grate pellet plant. CFD Modelling was used to optimise and validate burner design, ensuring optimal flame shape and length, as well as fuel consumption.

RUSSIA: Eurocement, Belgorod

FCT has been awarded a contract to deliver a Gyro-Therm™ burner for natural gas and solid alternative fuels for kiln 7 in Belgorodsky cement plant. The main target of the project is to reduce fuel specific consumption and allow for solid alternative fuel injection. Delivery is expected for July 2021 with commissioning shortly after.

RUSSIA: Eurocement, Ust-Dzheguta

FCT has been awarded a contract to deliver two Gyro-Therm™ burners for natural gas and solid alternative fuels for kilns 2 and 4 in Kavkazcement plant. The main target of the project is to reduce fuel specific consumption and allow for solid alternative fuel injection. Delivery is expected for July 2021 with commissioning shortly after.

RUSSIA: Eurocement, Fokino

FCT has been awarded a contract to deliver four Gyro-Therm™ burners for natural gas and solid alternative fuels for kilns 8, 9, 10 and 11 in Maltsovsky portlandcementplant. The main target of the project is to reduce fuel specific consumption and allow for solid alternative fuel injection. Delivery is expected for July 2021 with commissioning shortly after.

RUSSIA: Eurocement, Nevyanskiy

FCT has been awarded a contract to deliver one Gyro-Therm™ burner for natural gas and solid alternative fuels for kiln 1 in Nevyanskiy cementnikplant. The main target of the project is to reduce fuel specific consumption and allow for solid alternative fuel injection. Delivery is expected for July 2021 with commissioning shortly after.

RUSSIA: Eurocement, Stariy Oskol

FCT has been awarded a contract to deliver two Gyro-Therm™ burners for natural gas and solid alternative fuels for kilns 4 and 5 in Oskolcement plant. The main target of the project is to reduce fuel specific consumption and allow for solid alternative fuel injection. Delivery is expected for July 2021 with commissioning shortly after.

SOUTH AFRICA: Undisclosed client

FCT is conducting a CFD study for the selection of a new burner system to Top Submerged Lance (TSL) Smelter.

TURKEY: Deha Industry, Kayseri

FCT has delivered a burner for a new zinc recuperation kiln in Kayseri, Turkey. the main fuel is natural gas. As part of the complete scope, FCT supplied the burner, natural gas valve train, burner management system, primary air fan, igniter, flame sensor and minor accessories. Commissioning is underway.

USA: Imerys, Andersonville

FCT has delivered Gyro-Therm™ burners for both kiln lines 1 and 2 at the Imerys plant in Andersonville. The scope also included Burner Management Systems, trolleys, fans, igniters, flame sensor.

USA: Ash Grove Cement, Chanute KS

FCT has been awarded the contract to supply a new multi-fuel burner for the cement kiln in Chanute Plant. The new Turbu-Jet™ burner system will be able to fire up to 100% coal/petcoke, natural gas and 40% liquid waste.

USA: US Silica, Vale OR

FCT has been awarded the contract to supply a safety system upgrade for Kiln 1 installed in US Silica’s plant in Oregon. The project aims to update the existing natural gas valve train to comply with the latest NFPA safety requirements including a new ignition system. A new burner management system will also be installed.

PEOPLE OF FCT

At FCT, we know that our continued success is largely due to our team’s commitment to providing the best products, service, and expertise across all our offices. We are pleased to announce the newest additions and changes within our team:

Adriano Greco, Chief Executive Officer, FCT International

We are pleased to announce that Adriano Greco has accepted the position of FCT Group CEO, and commenced in this position from June 1. Based in Florida, Adriano has been CEO of FCT-Combustion’s American business unit since 2015 and has also implemented the Brazilian subsidiary. Adriano brings over 20 years of extensive pyro-processing industry experience from management roles across the USA, Brazil, China, Austria and Spain having previously held positions such as President of Greco Combustion Systems and Director of Gebr. Pfeiffer, Inc. To read more about this appointment, please click here

Andrew Witts, Chief Financial Officer, FCT International

We are pleased to introduce Andrew Witts as Chief Financial Officer of the FCT Group. Andrew has extensive experience working with multi-national organisations including CCL Industries, Itron, and Sony (UK). With a MSc Commercial Strategic Business Management from Manchester Metropolitan University, Andrew is also a member of various professional accounting associations across Australia, the UK and the US. Andrew commenced in this role in February 2021.

Andy Bailes, Chief Executive Officer, FCT Combustion (Asia Pacific)

We welcome Andy Bailes as the new CEO of FCT-Combustion (Asia-Pacific). Andy joins FCT after almost 30 years at Metso in Australia, having spent 10 years as General Manager – Engineered Product Services where he was responsible for managing a large team covering proposals, sales, technical, commercial and contractual obligation of the EP Products (Grinding, Pyro, Process & BMH) Group within ANZ Region. Andy started in this new role in April 2021. To read more about this appointment, please click here

CONFERENCES & EVENTS

AISTech 2021, Nashville (USA), 29 June to 1 July 2021

FCT Combustion Inc will exhibit at AISTech – The Iron & Steel Technology Conference and Exposition from 29 June, booth # 1852, which will be held at Music City Center, Nashville, Tennessee. For more information about AISTech, click here

Find out why FCT is the #1 supplier of burner systems to the iron ore pelletizing industry worldwide

At FCT Combustion, our trusted technologies are proven to deliver performance through reduced fuel usage, lowered emissions, improved safety, and increased fuel flexibility. As an industry leader, we have delivered more than 800 combustion systems to our valued clients within the iron and steel industries over the past decade.

Our dedicated, specialist team have significant experience successfully optimizing pyro-processes across various environments and different fuel types, to consistently deliver performance. Our proprietary equipment and technology, coupled with our comprehensive project management system, means we can deliver cost effective combustion solutions of the highest quality, in any region of the world.

Whether your process uses a grate-kiln or straight/traveling grate, FCT has the best combustion solutions and expertise to optimize your process. As the trusted industry experts to deliver performance, we are committed to delivering the best combustion solutions to optimize your process and operations.

Download the brochure

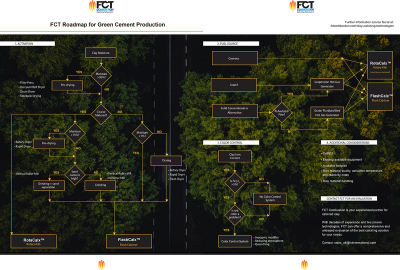

Road map to green cement production

Green cement is being considered by the global cement industry as a strategy to reduce carbon emissions and simultaneously deliver economic benefits to producers. FCT have developed FlashCalx™ and RotaCalx™ specialist clay calcining technologies to assist producers in achieving these benefits, as well as developing a proprietary solution to ensure the traditional ‘cement grey’ colouring is maintained in the final product.

Joel Maia, CEO of FCT-Combustion GmbH (Austria) and Pedro Madeira, Technical Director of FCT-Combustion Inc (USA) provide an overview of the green cement production process in this article available for free download.

At FCT, we have compiled the specialist knowledge of our dedicated team with proven experience in calcining clay for more than four decades. Included within the article, and below, is a simple diagram to assist those interested in clay calcination. The general guide helps select the best method for different types of raw material characteristics and environment, as well as equipment selection.

However, each individual project needs to be assessed on a case-by-case basis to ensure best outcomes. Our team are ready to assist, and can be contacted to discuss your specific case in more detail. Please don’t hesitate to contact your local office

This article was originally published in ZKG Cement Lime Gypsum (www.zkg.de)