FCT COMBUSTION NEWSLETTER: August 2024

Dear Friends,

I hope this newsletter finds you happy and healthy.

The first semester of 2024 has been a fruitful one for FCT, and we are pleased to share some of our successes with you in this edition of the newsletter.

It is our mission to develop and deliver pyro-processing solutions to assist our partners meet their sustainability goals, and which contribute to the decarbonization of heavy industry.

Hydrogen research is one way in which we seek to make a difference. As a member of the Heavy Industry Low-carbon Transition CRC (HILT CRC), we have been conducting tests on several new environmentally friendly new technologies, which can be applied to the different industries we serve, such as cement, lime, iron ore, metals and other minerals. We’ve also been awarded a contract to design and supply burners for one of the biggest hydrogen projects in the world.

We have a full range of pyro-processing equipment, including burner systems for rotary and straight grate kilns, hot gas generators, calciners, and fuel handling systems. We are pleased to be at the forefront of pyro-processing research, and proud that we can offer this technology to our customers.

Another strategy to reduce CO2 emissions in heavy industry is the use of calcined clays for the production of ‘green’ cement. Our team has more than 4 decades of experience working with calcined clays and we have developed two calciner technologies to suit the needs of our clients in this area: RotaCalx rotary kiln calciner and FlashCalx flash calciner.

We have spoken at many high-profile industry events on the topic, with a recent highlight being the International Conference on Calcined Clay for Sustainable Concrete in Nanjing. Our Sustainability Director Pedro Ladeira was invited to be a speaker at the event, which was a great honor. Pedro spoke about how to optimize plant configurations for energy-efficient calcined clay manufacturing – a topic which we receive many questions about. This year alone, we have already conducted clay projects for more than 22 clients.

We’ve also made phenomenal breakthroughs to ensure a traditional ‘cement grey’ end-product and avoid the clay turning the cement into a reddish hue. Our proprietary solution using inorganic modifiers is the only one of its kind available in the market that we know of, and the innovative color control technique has lower impact in emissions and energy consumption while also allowing for an improvement in calcined clay quality. If you’re interested in more information on this topic, please click here.

Last but definitely not least, we are very excited to share that we have opened a new office in Vitoria, Brazil. This new office is a major milestone for FCT, demonstrating our consistent growth and expanded operations. We are confident that this new space will allow us to further enhance our client services within the region, particularly to the iron ore pelletizing and cement industries.

I hope that you will enjoy reading our latest newsletter, and please do not hesitate to contact our team anytime if we can be of assistance. You can contact us via our contact page or follow us on LinkedIn

Wishing you all the best,

Adriano Greco

FCT Group CEO

PROJECTS ACROSS THE GLOBE

RECENTLY COMPLETED OR CURRENTLY ACTIVE PROJECTS ACROSS FCT COMBUSTION INCLUDE:

AUSTRALIA: Rio Tinto, Yarwun

FCT has been awarded the contract to design and supply burners for natural gas and hydrogen, along with valve trains for natural gas, hydrogen, and O2 and a burner management system for Rio Tinto’s 50-70MW hydrogen-fired calciner at the Yarwun alumina refinery in Gladstone, Queensland.

Hydrogen will be used on a trial basis to replace natural gas partly with an aim to eliminate CO2 emissions from the combustion process in future. This is an important step in Rio Tinto’s path towards decarbonizing alumina refining. Australia is the world’s largest producer of bauxite and the largest exporter of alumina.

AUSTRALIA: BHP Olympic Dam

FCT delivered and commissioned an oxy-fuel burner package for BHP’s flash smelting furnace at Olympic Dam in South Australia. The upgrade will extend the life of the furnace. In addition to the custom burners for both the North and East walls of the Settler Bath, accompanying burner management systems, valve trains, oxygen analysers and ancillaries are also included within the scope.

AUSTRALIA: Albermarle, Kemerton

FCT has been awarded the contract to deliver the burners, valve trains, gas analysers and burner management systems for Lines 3 and 4 of Metso’s lithium pyro-plant in Kemerton, Western Australia. The project follows the successful delivery of Lines 1 and 2 at the same plant, with the commissioning of Line 1 already complete.

BRAZIL: Undisclosed client, Araguaia

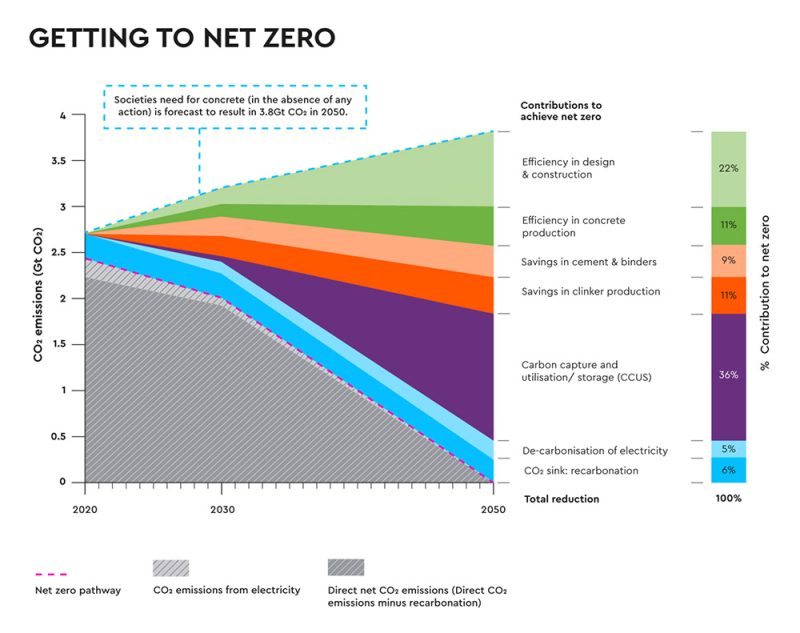

FCT has completed the supply of a 52MW Hot Gas Generator that will be installed in a Nickel product greenfield facility in Brazil. This project was conceived to the fired with HFO, and diesel oil. Equipment is delivered and is waiting for mechanical assembly.

The hot gas generator chamber before assembly

EUROPE: Undisclosed Country/ Client

FCT has been awarded a contract as part of a Pellet Plant Refurbishment Project to supply 38 combustion systems and peripheral equipment and services for natural gas, coke oven gas, and hydrogen in the future. The main goals of the project are to have new combustion systems with a large turndown ratio on all fuels, allowing safe and smooth operation from the beginning of kiln preheating up to full production, while controlling NOx emissions. The scope of supply includes burners, burner blocks, igniters, flame sensors, fuel valves and safety equipment, combustion air fans with distribution manifolds, and a CFD study. The equipment has been delivered, and commissioning is scheduled for the end of 2024.

EUROPE: Undisclosed Country/ Client

FCT has been awarded a contract for a new combustion system comprising a main and satellite burners for the clinker kiln for up to 100% solid alternative fuels. Other fuels of this system are liquid alternative fuels, natural gas, and coal as backup fuel. The targets of the project are to maximize the usage of alternative fuel, decreasing the CO2 emissions of the line. The scope includes accessories and spares. The delivery is foreseen by the end of 2024 for expected commissioning in the winter stoppage in 2025.

EUROPE: Undisclosed Country/ Client

FCT has signed a contract to supply a new combustion system which comprises a main burner for the clinker kiln for up to 80% solid alternative fuels. The burner is also designed to burn coal and natural gas. The targets of the project are to increase the usage of alternative fuel, decreasing the CO2 emissions of the line. The scope comprises accessories and spares parts, including a complete spare burner. The delivery is foreseen by the end of 2024 for expected commissioning during the next winter stoppage in 2025.

EUROPE: Undisclosed Country/ Client

FCT has been awarded a new contract for a new combustion system package for clinker production. The complete package includes two burners for the calciner and main and satellite burners for the rotary kiln, accessories and valve trains for the burners and CFD studies. This new burning package is part of customer’s plan to reduce CO2 emissions, allowing utilization of alternative fuels above 90% in the main burner. Coal is not going to be used at the new burners. The delivery of the package is planned for the first quarter of 2025.

INDIA: Birla Corporation

FCT has delivered Birla Corporation with a calciner for firing petcoke and coal.

NAURU: Republic of Nauru Phosphate Corporation (RONPHOS)

RONPHOS has two rotary fryers for drying phosphate rock, each with its own hot gas generator. FCT has delivered a combustion system including one oil burner, a primary air fan, an oil pumping skid, an oil valve train, and Burner Management System. The combustion system is designed to utilize both waste oil and diesel.

TAIWAN: IHC Mining/ Chemours, Kuan Yin

FCT delivered a combustion system for IHC Mining’s Recovered Ore (RO) Dryer at Chemours Kuan Yin Rutile (TiO2) plant.

USA: Lhoist, O’Neal

FCT supplied Lhoist’s O’Neal plant in Alabama with a Gyro-Therm™ burner and accessories.

The Gyro-therm™ burner was delivered to Lhoist’s O’Neal plant

USA: GCC Cement Company, Trident

FCT supplied a complete Turbu-Jet™ burner and accessories to GCC’s Trident plant in Montana.

USA: Penta Industrial Corp, Eden

FCT has been awarded a contract to deliver a Hot Gas Generator system to the plant in Wisconsin.

USA: ThyssenKrupp, Odessa

FCT has been awarded a contract to deliver a Gyro-Therm™ burner, Burner Management System, Valve Train, Trolley, and accessories. The project is scheduled to be delivered in late 2024.

USA: Cheney Lime & Cement Company, Alabaster

FCT is supplying Cheney Lime & Cement Company with two complete Gyro-Therm™ burners for their Lime product kilns, later in the year will also supply the plant with other two spare Gyro-Therm™ burners.

PEOPLE OF FCT

At FCT, we know that our continued success is largely due to our team’s commitment to providing the best products, service, and expertise across all our offices. We are pleased to announce the newest additions and changes within our team:

Átila Soares, Sales Manager for Europe and Africa

We are delighted to introduce Átila Soares, who has joined FCT Combustion as Sales Manager for Europe and Africa! Átila is based in our office in Vienna, Austria.

Átila joins us from AUMUND Group, where he has held several roles over the past 18 years including Sales Manager for the past 7 years. He also holds a Mechanical Engineering degree from Faculdade de Engenharia Industrial (FEI), Brazil.

With a wealth of experience across all areas of sales, including strategic planning, new business development, negotiations, contracts, and nurturing partnerships, we are pleased to have Átila on our team to support our ongoing growth within the European and African regions.

Aloisio Telles, Sales Manager for North and South America

We are pleased to welcome Aloisio Telles, who has joined FCT Combustion as Sales Manager for North and South America!

Aloisio has more than 20 years of experience in projects in the cement and mining sectors, and joins us from AUMUND Group where he worked for more than 12 years in roles across Sales, Contracts, and Supply Chain coordination.

Previously to this, Aloisio also worked in sales, technical, and project management roles for companies such as St Mary’s Cement (Votorantim), MCM Montagens Industriais, AmBev, and Maquinas Piratininga Industria e Comercio Ltda.

Aloisio has a degree in Mechanical Engineering from Universidade Federal de Pernambuco, an Executive MBA in leadership and Management from Saint Paul Escola de Negocios, as well as being Greenbelt certified in Six Sigma.

Leandro Brandão, Business Process Manager, FCT Group

We are thrilled to introduce Leandro Brandão, who has joined FCT in the role of Business Process Manager, working across all business units of the FCT Group of companies internationally.

Leandro is an experienced change agent who has consulted for large companies in various segments around the world, and has spent the past 17 years developing, training, and implementing management and leadership development practices focusing on innovation, operational excellence, and value generation.

Leandro originally trained as a Mechanical Engineer, graduating from Centro Federal de Educacão Tecnológica de Minas Gerais before completing his MBA at Fundação Getulio Vargas. Leandro has also undertaken further studies focusing on innovation and growth at Harvard University, Massachusetts Institute of Technology, and Singularity University.

Tapas Bhowmik, Engineering and Projects Manager, Asia-Pacific

We are happy to introduce Tapas Bhowmik, who has joined FCT as Engineering and Projects Manager across the Asia-Pacific region. Tapas is based in our office in Adelaide, Australia.

Tapas holds a Bachelor of Mechanical Engineering and brings a wealth of project management & project engineering experience to the role having previously worked primarily in the Oil & Gas industry in Asia and the Middle East for companies such as Saudi Aramco, Jacobs, Aker Solutions, Sembcorp Marine, and Larsen & Toubro.

CONFERENCES & EVENTS

On September 16-18, FCT will attend FICEM, booth 54 in Cartagena, Colombia

FCT will exhibit and give a presentation at the Global CemFuels conference being held in Dublin from September 18-19, on the topic “Decarbonisation Roadmap: Process optimisation, calcined clays, alternative fuels and hydrogen – Diverse strategies for a cost-effective approach”.

On October 8-11, FCT will exhibit at the International Lime Association conference being held in Oslo, Norway.

On October 10, Joel Maia will speak at the Carbon Zero conference being held in Madrid on the topic of “Reducing CO2 emissions in Cement and Clinker Production: Pathways to a Sustainable Future”

FCT Combustion is sponsoring the Fastmarkets Middle East Iron & Steel 2024 in Dubai from November 18-20. Come and meet the team in Booth B51!

Aloisio Telles, Sales Manager, and Paulo Mazzei, CBDO, were pleased to attend the SEMTEC conference held in Brazil last month. It was great to see our customers, associates, and friends at the event and we look forward to the next one!

Michael Zhu and Pedro Ladeira were delighted to attend the 4th International Conference on Calcined Clay for Sustainable Concrete (ICCSC) in May, where Pedro Ladeira presented on the topic “Optimizing Plant Configurations for Energy-Efficient Calcined Clay Manufacturing”

FCT opens second office in Brazil

We are delighted to announce that on July 11, FCT Combustion opened a new office in Vitoria, Brazil! The Vitoria office is the second Brazilian office for FCT, with the other located in São Paulo.

Possessing full Project and Service capabilities, the office in Vitoria comes in response to consistent growth and a need for expanded operations in the region. We are confident that this new space will allow us to further enhance our client services for Latin American customers.

FCT Combustion also has offices in Fort Lauderdale (USA), Vienna (Austria), Adelaide (Australia), and Nanjing (China). To find and contact your local office, please click here

Clay Calcining

FCT Combustion offers two clay calcining technologies for the production of Green Cement: FlashCalx flash calciner and RotaCalx rotary kiln calciner.

We have two pilot plants in Brazil, in which we have made more than twenty tests in the last 12 months for clients. In the video, you can see the test rigs we use to test our client’s material before they move to the industrial size installation.

The test rigs are fully operational and we are able to test with or without colour control for our clients, depending on their wishes. FCT has a unique and innovative colour control technology using inorganic modifiers, which ensures the traditional ‘grey’ colouring.

Our specialist team have more than 4 decades of experience in clay calcining and are ready to help you. For more information about clay calcining, including presentations and downloadable materials, please click here

Burner Q&A

In the June edition of World Cement, FCT participated in a burner Q&A session. Read below to learn more about optimal burner design for different fuel types, emissions reduction, improved performance, and increased productivity.

Different fuel means different particle sizes, densities, moistures, and calorific values together with different drying, ignition, and burnout times as well as combustion kinetics. The type of alternative fuel, the variation in types and the ratios in which they are delivered to the burner can impact on flame length and heat flux profile inside the kiln as well as emissions. Most fuel dosing systems are also working on volumetric basis, which means that the thermal energy being supplied to the burner is variable over time, even if the volumetric dosing is constant, due to the variable fuel characteristics.

To mitigate all these effects, the burner must be designed to allow very flexible operating in such a way to allow for proper aerodynamic and combustion control, enhancing entrainment of secondary air into the flame. FCT recommends the use of our Turbu-Flex™ Burner with its unique axial air tip design, reconfigured swirl, alternative fuel lofting air which is split between lifting the material from the bottom of the conveying pipe and dispersion air which disperses the fuel into the primary and secondary air as it leaves the burner tip.

Apart from the challenges at the kiln burner, it is important to mention that some fuels are inherently better suited to the calciner, and it would not make sense to overcome the difficulties of using them at the kiln, when it would be much easier to use them at the calciner. Such fuels include those with higher moisture, lower calorific value, larger particle size, longer required combustion time, or low volatile content, among others.

As a general rule, easier to burn alternative fuels should be targeted at the kiln burner, and harder to burn fuels at the calciner. In case there is no calciner available, a mix between hard and easier to burn alternative fuels would be the best compromise to increase the overall substitution rate, with lower impact on the kiln operation. Another solution could be the use of satellite burners, which is further detailed in the next questions. CFD modelling could also be a good option for specific problem solving.

The use of hydrogen as a fuel in cement production is also an emerging trend which can impact burner performance. Due to its high cost and low availability at present, hydrogen could be considered an alternative fuel in the short to medium term. Production of hydrogen through electrolysis also produces oxygen, so that the availability of either or both for the burner systems opens new possibilities for control of flame characteristics optimised for cement production.

There are a number of considerations, including:

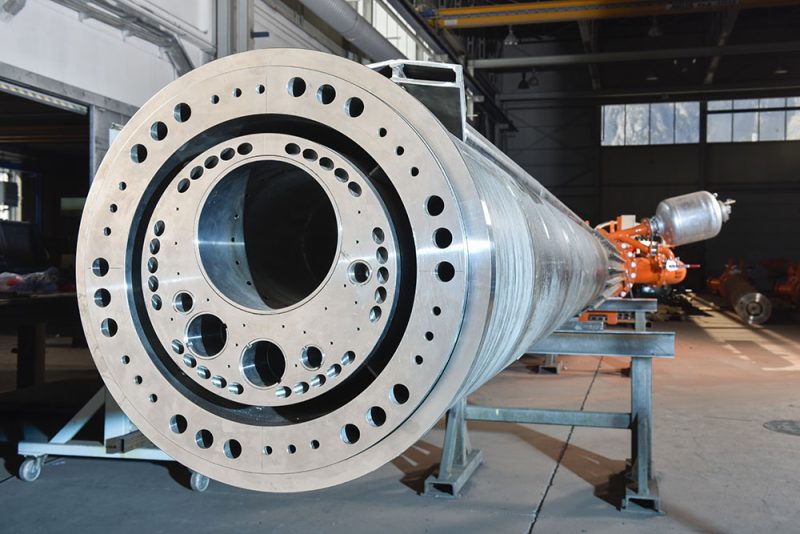

In the main burner radiation heat transfer is dominant and hydrogen produces very little radiative heat transfer compared with solid fuels or carbon sooting fuels (like HFO and to some degree natural gas). Therefore the use of Hydrogen along with AF’s such as RDF or biomass, bio-oils, and similar, is necessary to maintain sufficient radiation from the flame.

Hydrogen on the other hand has a very fast flame speed, wide flammability range in air (4-75% cf Natural Gas 5-15%) and low ignition energy (100x lower than gasoline) meaning that hydrogen will help to stabilise the flame and provide more heat closer to the burner tip and therefore dry and devolatilise the RDF more quickly.

Hydrogen burnt in air produces a very high flame temperature which can lead to high Nox emissions therefore once again the use of hydrogen with AF’s can be beneficial with the moisture from the AF’s suppressing the peak flame temperature and keeping Nox emissions under control.

Hydrogen has a propensity to leak as Hydrogen is the smallest molecule. Therefore more attention needs to be given to connections such as flanged and threaded joints and the hazardous area rating around valve trains and the burner may impact the instrumentation selection in the region of these.

From a safety aspect consideration needs to be given in fuel handling, burner design and burner management system (safety controls) as the explosion severity for hydrogen is 10x that of methane and therefore the safety integrity of hydrogen safety systems need to be 10x or more than that of natural gas and other fossil fuel systems.

If a cement producer wishes to increase alternative fuel usage at very high levels, the ideal course is to adopt a custom burner designed for their fuel type(s). However, if this is not possible, whatever the reason, the use of a satellite burner is a good way to introduce more alternative fuels into the process.

The satellite burner is a piece of equipment that injects the AF directly at the hot secondary air, recessed from the burner and a bit higher up in the kiln. It has additional primary air injection to provide cooling and especially some turbulence and mixing of the AF particles with the secondary air. During the travelling time of the RDF between the satellite burner injection and the main flame, there is a drying, preheating and devolatilizing effect, improving the combustion of this AF when it comes to the main flame.

The Satellite burner is a good entry or complementing option for injecting AF in the kiln because:

- It is easy and cheap to implement.

- It allows the use of ‘worse’ AF (larger particles, 3D particles, higher moisture) in the kiln as it provides drying and preheating before combustion.

- It injects the AF in a high O2 environment.

However, the satellite burners have their limitations in terms of TSR, which is around 40-60% depending on the conditions in the kiln, because:

- Above that threshold, it is not good for the clinkerization process and clinker quality to shift fuel away from the center of the kiln.

- The control and mixing over the AF particles is somehow limited.

- The satellite does not have the full capability of a modern high AF burner, therefore it has more difficulty to handle larger amounts of fuel.

It is generally believed that minimizing primary air amount is one way to reduce NOx generation at the burner. However, in practice, the answer is not so simple. In isolation, the reduction of primary air amount can lead to an increase in NOx if it causes a delayed ignition of the fuel, for example. Apart from that, the reduction of primary air alone can also affect clinker quality, decreasing cement strength and can cause issues with the kiln operation in terms of slower responsiveness, increased alkalis and sulphur cycles in the kiln, and uncontrolled combustion.

The important point is that NOx emissions can be minimised with reduced primary air, as long as it comes with the same or better combustion control. Apart from the quantity of primary air, the distribution in the flame can have a significant impact on NOx emissions. Delayed entrainment of secondary air can decrease NOx, as long as it does not cause delayed fuel ignition. Early ignition of the flame has long been known to reduce NOx and burner tip and primary air design is critical to the ignition point. The location and momentum of the primary air at the burner tip is critical in how and where secondary air is entrained into the flame. It should allow for a fast fuel igniton but a slower combustion overall – a very fine balance. Water injection into the flame from the burner tip can also be useful in controlling peak temperatures which are another factor in NOx generation, but obviously it has its penalties.

Where possible, a very effective and economically advantageous strategy to reduce NOx emissions is to use alternative fuels. Their characteristics such as higher moisture, larger particle sizes, or low calorific values, among others are such that they slow down the combustion. Fuels with lower nitrogen content can also be used to reduce NOx, though with limited results. A flexible burner that can be adjusted to different conditions and fuels is paramount.

The actual burner technology can in some cases have a huge impact on NOx emissions, for example, the Gyro-Therm™ burner for natural gas uses completely new technology for mixing fuel and air that minimises NOx formation while producing a short hot heat flux profile ideal for cement kiln operation.

Generally speaking though, it is undesirable to compromise product quality, kiln output, fuel consumption, refractory life etc to control NOx emissions, and it is better to treat the Flue Gases to remove NOx from the exhaust stream.

The interaction of the flame and kiln aerodynamics can be a critical determinant of refractory life. The burner design drives the heat flux profile, which is a key driver of coating building and stability. Good stable coating in the burning zone is the best way to increase refractory lifetime in the kiln region under the most thermal stress.

However, the burner works in a certain environment, which is different in each kiln. The burner design should be tailored to the unique kiln in which it is installed, taking into consideration specificities in terms of secondary air conditions, kiln, kiln hood and cooler geometries, temperatures in different streams and parts of the process as these can influence reasonably how the burner should be designed, how the flame and kiln heat flux profile are affected, and how these impact on stable coating, and volatile cycles among other factors. In some extreme cases, such as when a new burner is being sought to solve an existing problem in the kiln, modelling can be an effective tool for optimisation.

The fundamental design choices underlying the burner’s architecture can have a major effect on the lifespan of the burner itself. Moving elements at the front of the burner are key weak points, where wear or thermal damage can cause significant alteration of the burner’s performance, potentially leading to kiln refractory damage. FCT’s design philosophy is based on simple and robust construction methods which are intended to maintain the aerodynamic integrity of the burner, coupled with science and modelling driven detail design aimed to meet the specific kiln’s operational requirements.

The right choice of materials against wear, as well as better instrumentation to monitor and adjust operating conditions, are extremely important for extended burner lifetime. FCT is also a pioneer in the use of innovative thermal treatments on burner tip components to improve cooling. Burner thermal management is a very important component in the work required to extend burner operational lifetime and the ability of the burner to survive adverse events such as power failures.

A design which is maintenance-friendly is paramount to bring the burner back to its original state if a problem does occur.

The next steps in burner design depend which global region is being considered, as different areas have different environmental concerns, expectations, fuels, different stages of technological development, and so on.

In very broad terms, obvious next steps are going to be in the utilisation of hydrogen and oxygen due to their environmental appeal on CO2 reduction. Depending on the very many supply possibilities, these may be available and used either separately or together, in quite small or potentially quite large quantities.

In terms of alternative fuel usage, we may continue to see utilisation of ‘worse’ AF, including fuels with larger particles, 3D particles, or higher moisture, and this should be considered in the burner design. In the AF area, we may also see a higher focus on oxy-fuel mode capabilities in either a partial or full capacity.

Apart from the obvious challenges of incorporating hydrogen into the process, such as cost and availability, another consideration is the effect hydrogen-firing can have on flame radiance. To ensure flame radiance is optimal, there are two main options: a design allowing small quantities of hydrogen to enhance the use of alternative fuels or alternatively, for higher quantities of hydrogen, the design may consider dual-firing with carbon-based alternative fuels.

Novel materials and treatments are likely to feature in near future designs, particularly in the areas of wear and thermal management.

Modular burner designs might well become the norm where plants are forced to adapt to rapid changes of their available fuels. Rather than designing a burner for several different fuel that may or may not come into operation, which may compromise the overall design in benefit of the flexibility, it may prove substantially better to provide and easily upgradeable burner with replaceable sections that allow a smaller set of conditions (for example, fuels), to be used closer to their optimum design.

Looking further ahead, the availability of real time information on kiln operating conditions could lead to kiln modelling and some automated burner adjustments to maintain real time optimised burning conditions as process operations fluctuate.

Say bye to carbon dioxide: how to reduce CO2 in cement production

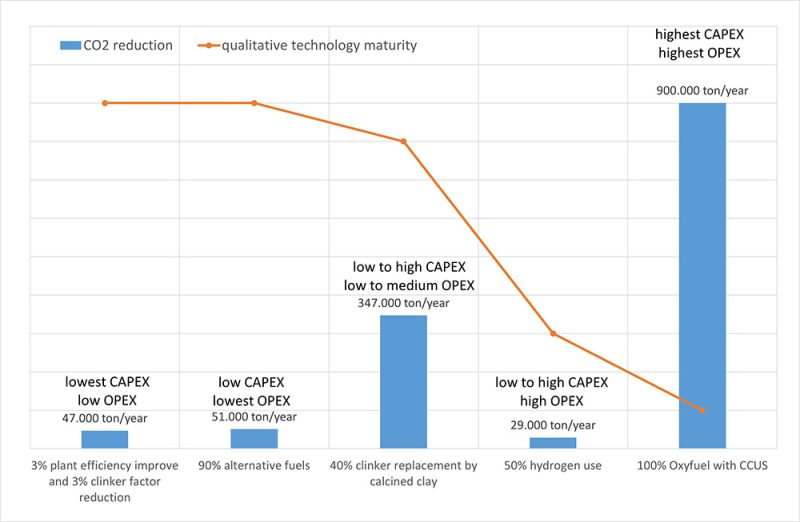

In this article, Joel Maia explores the different pathways available to producers to reduce CO2 from cement and clinker production. You can download the article by clicking here, or keep reading below.

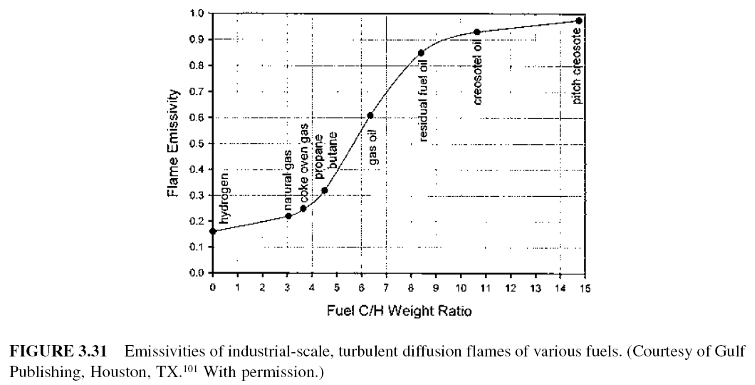

According to the Global Cement and Concrete Association, the construction sector produces CO2 in quantities estimated around 2.5 Gt/year, potentially increasing to 3.8 Gt/year by 2050 without CO2 mitigation efforts due to the rising demand for concrete. Approximately 60% of these emissions stem from limestone decarbonization, with the remaining 40% from the combustion of fuels used in clinker lines. Additionally, electricity consumption contributes indirectly to CO2 emissions, if the electricity is not produced in renewable ways.

The construction sector’s value chain, encompassing the 5Cs (Clinker, Cement, Concrete, Construction, and Carbonation) as per Cembureau, holds significant potential to reduce CO2 emissions, striving toward carbon neutrality. Achieving this goal requires a collective effort from all stakeholders in this complex puzzle, with clinker and cement production at its core.

Figure 1. GCCA’s net-zero parthway. Source: Global Cement and Concrete Association’s Cement Industry Net Zero Progress Report.

The industry has already been moving toward decarbonization for several years, employing various technologies. However, with numerous options available, plant environmental teams often feel overwhelmed, lacking clear information on the most cost-effective methods to reduce CO2 emissions for their specific circumstances. This article focuses on decarbonizing clinker and cement production, exploring different possibilities and proposing scenarios tailored to each plant’s stage on the decarbonization path.

Pathways for a Sustainable Future

CO2 emissions in clinker and cement production can be divided into two primary sources: emissions from raw material decarbonization and emissions from combustion. Several strategies exist to mitigate both, discussed in detail below. To facilitate comparison, we’ll use a hypothetical “standard kiln” with 4,000 tpd capacity, 800 kcal/kg thermal consumption, and a 40%-60% energy split between the kiln and calciner respectively, operating for 8.000 hours per year.

- Increase plant efficiency / improve clinker quality

Improving plant efficiency has a very broad meaning and has influence in all other methods presented as well. CO2 emissions are directly related to the amount of energy, thermal or electric, to produce 1 kg of material. Reducing the energy required to produce 1 kg of material lowers fuel consumption and the volume of gases generated, thereby reducing both thermal and electrical energy needs.

For instance, in the above-mentioned standard kiln, a 3% efficiency improvement would reduce CO2emissions by approximately 14.000 tons annually.

It might not seem much but considering that a 3% improve in the plant efficiency can be achieved by simple actions and low investment, involving better process control, reducing false air in the system, optimizing raw meal composition to allow for easier cooking, upgrading to a combustion system that allows the operation with lower oxygen content in the kiln while keeping the combustion under control are some examples.

Similarly, enhancing clinker quality can lead to significant CO2 reductions through the whole process. A better-quality clinker means that less clinker can be used, to achieve the same cement strength. A 3% reduction in the clinker factor due to better clinker quality in our standard plant scenario would decrease CO2 emissions by around 34.000 tons per year. Combining this with a 3% efficiency improvement results in a total reduction of approximately 47.000 tons annually.

Figure 2. A high-quality clinker can reduce the clinker factor in cement, therefore reducing the CO2emissions. Source: public domain

Methods to improve clinker quality include better process control, raw meal composition optimization and homogeneity, and investing in advanced combustion systems such as the Turbu-Flex™ from FCT.

These options are often overlooked powerful alternatives, at relatively low costs, to allow plants to contribute to their initial share of CO2 emissions reduction.

- Use of alternative fuels

It might sound counterintuitive that the use of alternative fuels would reduce CO2 emissions, as their combustion also releases CO2. While the combustion of alternative fuels also releases CO2, it prevents additional fossil fuel consumption and their associated emissions. Alternative fuels, often by-products of other industries, can replace fossil fuels, reducing overall carbon emissions. In this way, the carbon from the alternative fuels is once more reused after their primary purposes, instead of using a brand-new font of carbon taken from fossil fuels.

The use of alternative fuels is a mature technology, with plants in Europe being able to achieve up to 90% substitution rates by solid alternative fuels, and up to 100% when considering a mix of solid and liquid alternative fuels.

The cost of converting a plant to high substitution rates varies based on factors such as plant design, existing equipment residence times, the quality of alternative fuels that can be sourced /prepared, technology of the combustion equipment among others.

For our standard kiln, a 10% increase in thermal substitution rate replacing coal with RDF could reduce CO2 emissions by around 6.000 tons per year. Achieving a 90% substitution rate would reduce emissions by approximately 51.000 tons per year.

Figure 3. State-of-the-art Turbu-FlexTM burner from FCT for high substitution rates by alternative fuel. Source: FCT

Investments in CFD studies for the calciner and advanced combustion systems like the Turbu-Flex™ kiln burner from FCT are relatively low investments that can facilitate this transition.

- Replacement of clinker per supplementary cementitious materials

Materials that possesses binding characteristics when mixed with water or other materials, known as supplementary cementitious materials (SCMs), have been used for several decades as a clinker replacement. Fly ash from power plants running on coal, slags from steel production and natural pozzolanic material are common examples of SCMs. However, their availability is decreasing, prompting the search for alternatives, with calcined clay being a prominent option which is used in cement for over 40 years in some countries like Brazil for instance.

The clay used for the calcination is an aluminosilicate mineral within certain ratios of alumina and silica, containing hydroxyl in its structure. Once the clay is submitted to thermal treatment at the right temperatures, the hydroxyl is released from the clay structure. When the clay is mixed with cement, the Calcium oxide from the clinker will react with the clay, giving its strength. The right temperature for clay treatment is very particular of each clay, but in any case, it is below the clinkerization temperatures. Therefore, two benefits in terms of CO2 reduction can be achieved when replacing clinker by clay in the cement: the CO2 emissions from the combustion are reduced (there are further benefits if alternative fuels are used), and there are virtually no CO2 emissions from the material (except for some organic and limestone traces).

Once more, the investment costs of this possibility are within a very wide range. On one side, existing clinker kilns can be adapted for clay calcination with minor adjustments, offering a cost-effective solution, although not the most efficient, even with a pendular operation between clinker and clay. On the other side of the scale, new plants using rotary kilns or flash calciner technologies can be built for optimal efficiency, with an array of several different configurations. FCT offers the expertise of our engineers with more than 40 years in clay calcination and technologies like the RotaCalx™ (rotary kiln) and FlashCalx™ (flash calciner) for clay production.

Figure 4. dried and ground raw clay (top left), calcined clay without color control techniques (top right) and calcined clay with FCT’s patented color control process (bottom). Source: FCT

For our standard kiln, replacing 40% of clinker with calcined clay could reduce CO2 emissions by around 347.000 tons yearly.

- Use of hydrogen

Considering that hydrogen gas is a fuel that has no carbon, it should be considered ideal to reduce CO2emissions. So far, the use of hydrogen in cement production has been limited to very small amounts, in the range of single digits of percentage, from 0,2 to 3%. The limitation is rather in the production than in the combustion, especially when considering an environmentally friendly production of hydrogen. Nowadays, the vast majority, above 99%, of the hydrogen produced, is coming from the reform of natural gas which releases a substantial amount of CO2 to the atmosphere. If this is the case, burning natural gas directly in the kiln has a lower environmental impact. Apart from that, hydrogen is still expensive vis-à-vis other fuels and is not largely available to the industry hence it is not a feasible option at the moment for cement production.

In case environmentally friendly hydrogen, for example produced via electrolysis of water using solar or wind power, becomes available at affordable prices in the future, there are some challenges to use the hydrogen in cement production in large scale, including reduced flame emissivity, increased NOx emissions and distribution infrastructure for instance. However, these hurdles are effectively significant only when achieving a substitution rate by hydrogen above 50%. There are important investments in order to make hydrogen production more affordable, in larger quantities and clean. FCT wrote a comprehensive article in World Cement in November 2022 discussing the aspects around hydrogen usage in clinker kilns.

FCT’s burners are currently delivered for hydrogen use, ready for when clean and affordable hydrogen becomes available.

For our standard kiln, replacing 50% of coal with hydrogen would reduce CO2 emissions by around 29.000 tons per year.

- Oxyfuel process

Oxyfuel combustion is an innovative technology that can play a crucial role in reducing CO2 emissions in the cement industry. In a traditional cement kiln, fuel is burned in air, which contains about 21% oxygen and 78% nitrogen in volume. The nitrogen in the air does not contribute to the combustion process and instead ends up in the flue gas, diluting the CO2 concentration. Oxyfuel combustion, on the other hand, involves burning fuel with pure oxygen instead of air, recirculating part of the CO2 from the exhaust gases back to the cooler. This method results in a more efficient and intense combustion process and a significant reduction in nitrogen oxide (NOx) emissions. Oxyfuel combustion does not reduce the CO2 emissions per se, but it produces a flue gas that is rich in CO2, making it easier and more cost effective to be captured and stored or utilized.

This technology is new and has its challenges that need to be addressed, such as pure oxygen availability and costs, retrofit of existing plants as well as adaptations of the operational conditions.

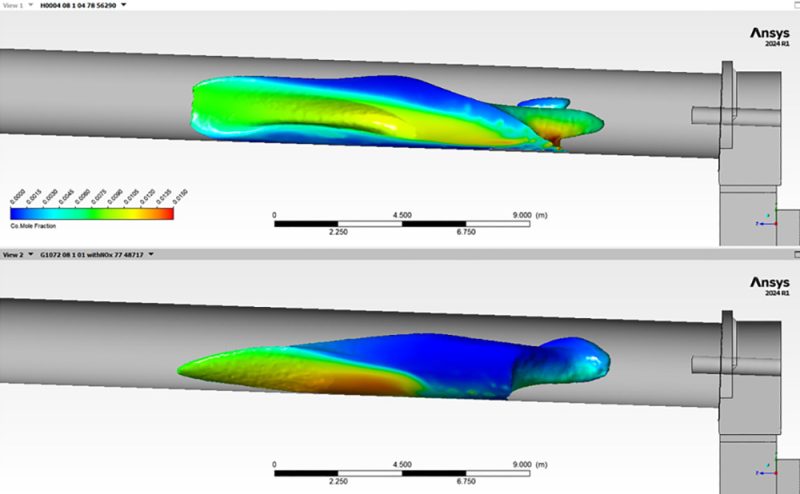

Figure 6. Combustion represented by an isotherm surface coloured by CO molar fraction, on top: oxyfuel combustion, at the bottom: conventional combustion with air. Source: FCT

Considering the standard kiln in this article, implementing oxyfuel combustion could lead to a significant reduction in CO2 emissions. With the ability to capture a high percentage of CO2 from the flue gas using a CCUS (carbon capture, utilization and storage) system, oxyfuel combustion could potentially allow the easier reduction of CO2 emissions by up to around 900.000 ton per year, depending on the specific conditions and capture efficiency.

FCT burners are designed to operate under oxyfuel combustion conditions with minor adjustments.

- Green electrification, Carbon Capture, Use and Storage (CCUS) and Others

There are few initiatives in the field of direct electrification and use of thermal carriers to replace the combustion in clinkerization processes. However, they are still very incipient and are further away in time when compared to the alternatives discussed here. The main challenges are to build reliable equipment and materials that can “deliver” 1450°C to the clinker, a reliable source of green energy throughout the year and the large amount of MWs required for the clinkerization. For a combustion process, 100 MW for instance is easily and inexpensively achievable, while for a green electrification, from solar energy for example, would require a few square kilometers worth of solar panels, a electrical sub-station and all the maintenance associated with these equipment.

Carbon Capture, Utilization, and Storage (CCUS) is seen as a major technology to help mitigate climate change by reducing greenhouse gas emissions from industrial and power generation sources by 2050. Industrial installations with different technologies are already in place, however, the high costs, energy requirements and necessity of practical experience collection of CCUS remain significant challenges for its widespread deployment for the moment. The intensive investments in this technology tend to revert this situation in the next years.

Apart from those, there are several other technologies, still in their infancy, which still require substantial research, investments, scaling up, to allow for their industrial use. It is an extensive topic that requires a complete separate article for proper discussion.

Conclusion

The cement industry faces significant challenges in reducing CO2 emissions, but numerous pathways exist to achieve substantial reductions, each one with its characteristics, challenges, costs and CO2 reduction potential.

It is important to mention that the solution toward CO2 neutrality is a combination of different methods.

Although at the end of the path, all plants would include most of technologies discussed, each plant is currently in a different stage of decarbonization. Each plant’s unique circumstances require tailored solutions. For instance, there would not make much sense for a plant to invest in calcined clay or hydrogen combustion, while the plant efficiency and use of alternative fuels is not maximized.

By improving plant efficiency, utilizing alternative fuels, replacing clinker with SCMs, and exploring hydrogen use, and the new advances and technologies yet to come, the industry can move toward a sustainable future.

Figure 7. Comparison between different technologies for CO2 emissions reduction. Source: FCT