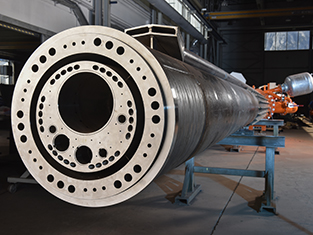

Turbu-Flex Burners

Industry Applications:

Rotary kiln burners for the cement industry

Product Details:

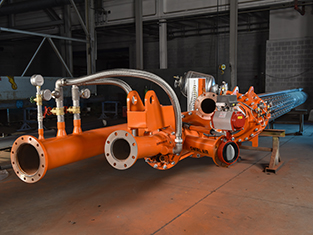

- Primary fuel: coal and petcoke

- Multi-fuel capability: can be used in combination with all fuels particularly alternate fuels:

- Liquids: solvents, oils, etc.

- Solids: RDF, sewage sludge, rice husks, etc.

- Firing capacities from small (10MW) to largest-scale (+150MW)

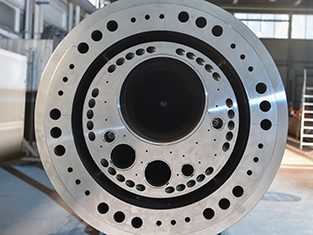

- Channels for pilot ignitor and flame sensor

- High temperature stainless steel faceplates; optional ceramic coating for additional protection

Benefits:

- Two easy operating modes:

- Low NOx ‘Standard Mode’

- ‘Boost Mode’ for firing high levels of alternative and low calorific fuels

- Flexibility to quickly switch between fuel types without impacting productivity

- No moving parts for precise primary air injection and smooth operation

- Low primary air requirement

- Long life faceplates, minimal maintenance costs