Process Production Managers and Kiln Engineers:

keep pace with changes to fuel, production and

emission regulations.

World leading products to optimize your kiln output and make

fluctuations in fuel prices work in your favor.

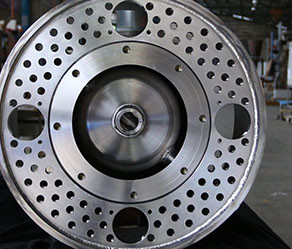

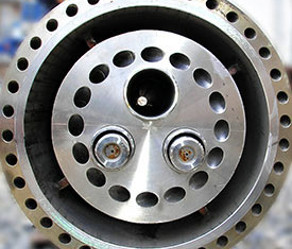

Gyro-Therm Burners

Industry Applications:

Rotary kiln for all industries (cement, lime, iron-ore, kaolin, etc.)

Benefits:

- Technology unique to FCT

- Increases gas flame radiation:

- Reduces specific fuel use,

- Lowest possible NOx

- Wide flame adjustment, using only gas, for great control of heat release

- Low primary air requirement

- High turndown, no warm up burner required

- Long life face plates, minimal maintenance costs

- Improved product quality and throughput

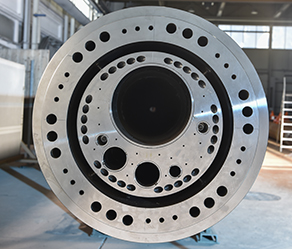

Turbu-Flex Burners

Industry Applications:

Rotary kiln for the cement industry

Benefits:

- Two easy operating modes:

- Low NOx ‘Standard Mode’

- ‘Boost Mode’ for firing high levels of alternative and low calorific fuels

- Flexibility to quickly switch between fuel types without impacting productivity

- No moving parts for precise primary air injection and smooth operation

- Low primary air requirement

- Long life faceplates, minimal maintenance costs

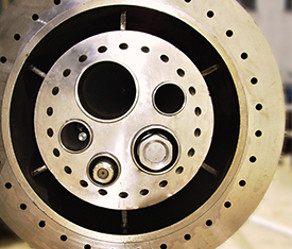

Turbu-Jet AF Burners

Industry Applications:

Rotary kiln for all industries (cement, lime, iron-ore, kaolin, etc.)

Benefits:

- Customizable design to suit all fuel requirements

- Fully flexible across a wide range of fuels

- High alternative fuel firing rates

- Great control of heat release

- Low NOx design

- Wide flame adjustment, using only primary air proportion

- Low primary air requirement

- High turndown, no warm up burner required

- Long life face plates, minimal maintenance costs

K-Jet Calciner Burners

Industry Applications:

- Preheater, calciner, riser, cross-flow and down firing for all industries

- Single or multiple burner configurations

Benefits:

- Customizable design to suit all fuel requirements

- Fully flexible across a wide range and combination of fuels

- Superior mixing for better fuel burnout and efficiency

- Even heat release and distribution reduces build up

- Long life face plates, minimal maintenance costs

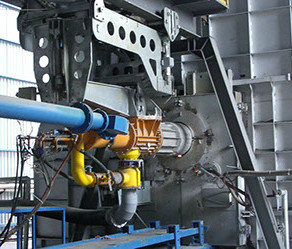

Hot Gas Generators

Industry Applications:

- Hot air for any process, suitable for all industries

Benefits:

- Accurate control of volume & temperature of hot air

- Can be designed to suit all fuel types including solid, liquid, gaseous, and alternative fuels

- Available in various configurations, including horizontal, vertical, and double shell

I-Jet Burners

Industry Applications:

Traveling grate kiln for iron-ore

Benefits:

- Long-life, robust design and construction

- Reduce specific fuel use

- High turn down ratio

- Proven low fire, cold start stability

- Low maintenance, long life and easy burner gun replacement

- Low primary air

- Proven low fire, cold start stability

Burner Management Systems

Industry Applications:

Safe management and control of any burner system

Benefits:

- Safe automated light up of burners

- Safety monitoring of burners during operation

- Stops fuels when preset limits are exceeded to protect plant and staff

- Extremely high reliability for longer life

- High integrity to minimize nuisance trips

- Rapid restart after stops

Solid Fuel Hot Gas Generator

Industry Applications:

For the generation of hot gases using crushed solid fuels. Applicable across a wide variety of industries. For use in spray dryers, dryers of all types, mills, boilers and other applications.

Benefits:

- Can replace equipment that uses traditional fuels such as natural gas, LPG or fuel oil – instead using solid fuels such as biomass, coal or petroleum coke to generate immediate savings

- Large burning capacity per m2

- Wide working temperature range of 200 – 900°C

- High combustion efficiency

- Easy operation and low maintenance costs

- Customizable action level

Moving Grate Hot Gas Generator

Industry Applications:

For the generation of hot gases using biomasses of difficult combustion and high humidity, such as mixtures of chips, tree bark and bagasse. Can be used for dryers and industrial ovens, among other applications.

Benefits:

- Mobile components move the biomass through the grid according to the different stages of combustion

- Can be adapted to boilers of the most varied types and models, reducing associated costs

- Burns renewable cycle fuels, providing environmental benefits as well as economic benefits

- Operates at different temperatures (up to 1,000°C)

- High combustion efficiency

- Operating flexibility

Clay Calcining Technologies

Industry Applications:

For the production of Green Cement.

Benefits:

- Choice of 2 technologies

-

- FlashCalx™ Flash Calciner

- RotaCalx™ Rotary Kiln Calciner

- Reduce clinker content with Supplementary Cementitious Materials, including calcined clay

- Flexibility to use the cheapest and most readily available fuels

- Decrease emissions and reduce operational costs

- Experienced team