Clay Calcining Technologies

for the production of ‘Green Cement’

With cement production responsible for approximately 8% of man-made CO2 emissions, several countries are adopting strict policies for greenhouse emission reductions.

One of the ways to reduce CO2 emissions caused by cement production is to replace clinker with Supplementary Cementitious Materials (SCM) such as calcined clay to produce what is known as ‘green cement’, named for its environmental benefits. Other key benefits include lower fuel consumption and lower capital costs.

At FCT, we have put together a specialist team who have successfully commissioned a combined 12 plants around the world for calcined clay cement. Eight of these plants were brownfield, and 4 were greenfield projects.

With proven experience in this growing industry, we have the necessary experience to evaluate and suggest the most suitable production method for each individual project. Our expert knowledge has shaped the development of two proprietary technologies for clay calcining: FlashCalx™, a suspension calciner, and RotaCalx™, a rotary kiln calcining solution.

Additionally, FCT has developed a unique and innovative colour control solution using inorganic modifiers to maintain the traditional ‘cement grey’ colour when using calcined clays – even in cases where the iron content in the clay is greater than 18%. Unlike many other colour control strategies, the use of inorganic modifiers is a relatively inexpensive method with reduced handling involved, and can deliver other, performance enhancing benefits.

Results from industrial trials with clients, and from tests in our pilot plant, have shown that when compared to other traditional methods, the use of FCT Combustion’s inorganic modifier colour control solution offers lower CO2 emissions, reduced energy consumption, and matched or improved concrete strength development.

FlashCalx™

A suspension calciner than can be installed with a mill or in an integrated plant.

FlashCalx™ combines the flexibility to use the least expensive and most readily available fuels, with the environmental and economic benefits of using flash calcining technology for sustainable cement production.

Available in standard sizes to optimize engineering and shipping costs, FlashCalx™ has a minimum footprint and can easily fit in new or existing plants with customization options available to suit different moisture contents, fineness and fuel types.

Existing equipment may be re-usable, such as a pre-heater tower, and in some cases, a dryer-grinder may be required depending on the moisture composition of the material. For such cases, a state-of-the-art hot gas generator will be installed, offering extreme fuel flexibility for liquid, gaseous, solid and alternative fuels without need for grinding.

Fuel usage: 450-600 kcal/kg (depending on raw material mineralogy)

Fuels: Oil, gas, petcoke (1 to 10mm), mineral coal (0 to 10mm), wood chips (10 to 30mm), biomass (including wood pellets, wooden briquettes, sugarcane bagasse and others), refuse derived fuels (RDF)

Key benefits:

Lower overall energy consumption

Quick set-up with a calcination time of just seconds

Low thermal inertia with limited refractory lining

Precise temperature control for highly reactive pozzolan

Only one grinding system is required

Static system results in less maintenance

Lower rate of under- or over- calcination

Quick return of investment

RotaCalx™

Based on a traditional rotary kiln. Suitable for either greenfield or brownfield projects.

FCT offers supply of new kilns and equipment, or alternatively, can match parts of old kilns or dryers with new equipment to complete the design and supply of a clay calcining plant. The re-use of an existing burner, hot gas generator, gasifier and other parts will reduce the associated capital expenditure.

Key benefits:

New or existing equipment

Drying and calcination in a single unit

Burner or combustion chamber

Utilization of de-commissioned machinery

Fast track

Easy operation

Broad range of fuels, with multi-fuel firing possible

Allows for coarser feed granulometry

Suitable for clays with higher moisture content

Watch our Webinars

Calcined clay: How to get started

Identifying the best calcined clay technology for different scenarios

Novel Colour Control Method for Calcined Clay Manufacturing

Additional Materials

Frequently Asked Questions

Cement is a crucial industry for the ongoing development of infrastructure globally, but the traditional cement production process creates approximately 8% of the world’s man-made carbon emissions.

The landmark Paris Agreement, supported by 196 countries across the world, strives to limit global warming to less than 2°C above pre-industrial levels. This has triggered a push to adopt stricter regulations to reduce greenhouse gas emissions by signatory countries.

Particular attention is being paid to industrial processes due to their energy intensive nature, which can have environmental impact on a broad scale. Additionally, this high use of energy can create economic inefficiencies for the producers themselves.

Green cement, so named for its environmental benefits, is regarded as a more sustainable solution with far reaching impacts by reducing the CO2 emissions and overall fuel consumption.

The move to green cement has been proven to:

- Significantly decrease emissions levels associated with cement production.

- Reduce operational costs for producers as less thermal energy is required.

Retain a high standard product for consumers with the potential for added benefits such as enhanced durability and increased plasticity within the concrete.

In Portland Cement production, pulverised limestone is a main ingredient in the raw mix, along with sources of silica, aluminium, iron, and other components. The mix is then pyro-processed at 1,450°C to produce clinker, the rock-like material that is ground down into powder and is the main constituent of cement.

During pyro-processing, the raw material is decarbonated, which is a necessary path to produce the cementitious mineral compounds in clinker resulting in significant CO2 emissions. Additionally, there are also CO2 emissions that vary according to the fuel source used to heat the raw materials to such high temperatures.

In the production of Green Cement, Supplementary Cementitious Material (SCM), processed between 600°C and 900°C, are used as a partial substitute for clinker in the final cement making process. Green Cement retains the cement strength of Portland Cement, and in some cases even improves plasticity. As in compound cement, less clinker is used and less heat is required to produce artificial SCM, less CO2 is emitted in the production process.

SCM can be defined as amorphous silico-aluminous material with hydraulically binding characteristics. There are various types of SCM that can be used in green cement, including natural volcanic materials, limestone, industrial by-products such as fly ash and slag, as well as natural or synthetic pozzolans.

As natural gas has become less expensive, and in response to the international CO2 reduction targets, power station operators are moving away from coal firing, which has resulted in both the reduced availability and increased price of fly-ash. Slag is also in high demand and not readily available anymore. As a result, pozzolans have become very popular SCM sources for green cement production, although suitable deposits of natural pozzolans can be scarce in some regions and challenging to access.

In such cases, or where uniformity is desired, synthetic pozzolans including calcined clay have become the premier choice of SCM. Clay is readily available virtually everywhere and deposits tend to be very heterogeneous, but clays used as pozzolans typically need Al2O3 to be in the range from 17% to 38%. The content of sand and other impurities can vary enormously, usually in a range from 5 to 50% and can include significant levels of iron oxide Another point to be considered is the moisture levels which can vary between 5 and 75%, depending on the source of the clay.

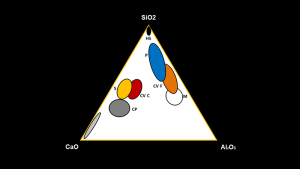

While Portland Cement is high in Calcium based compounds, pozzolan is chiefly a siliceous material, as demonstrated in Figure 1. Several types of clay can be used as SCMs after activation, with kaolinite, illite and montmorillonite being the most common types. Fineness of the clay after drying can range from a few micrometers to a few milimeters.

CaO-SiO2-Al2O3 ternary diagram. Portland Cement is shown as “CP”, and pozzolan is indicated by “P”

The activation of clay pozzolans are heavily dependent on three basic factors:

- Mineralogical composition of clay

- Crystallinity

- Optimal calcination temperature

The main aim of the industrial processing of pozzolans is to remove hydroxyl from the clay structure (as opposed to removing the carbon dioxide from the limestone structure in clinker production), and this process leads to the activation of alumina and silica oxides.

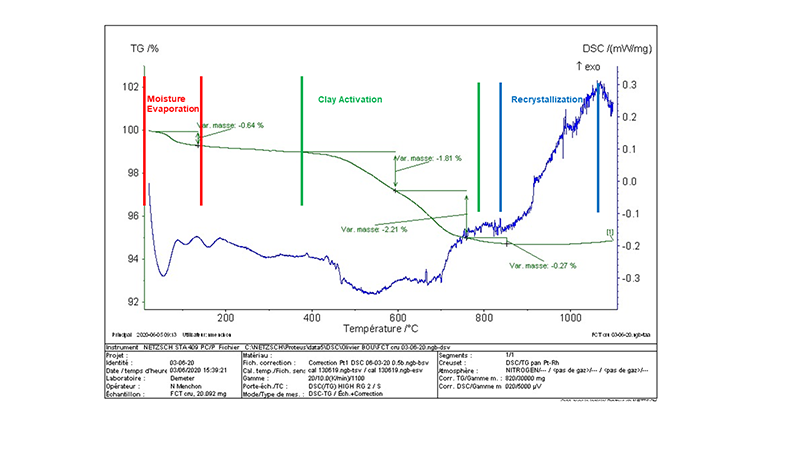

It is important to note that a low calcination temperature will not activate the clay completely and an excessive calcination temperature can cause the recrystallization of the clay structure, as shown in Figure 2. Both cases substantially decrease the reactivity of the clay. Of the clays mentioned, kaolinite is the easiest to work with because it has the widest temperature range for successful calcination. Some other clays, including montmorillonite, have a much smaller range at which they can be precisely heated to achieve activation before recrystallization occurs.

Thermogravimetric and differential scanner calorimeter analysis shows the temperature window for calcination before recrystallization occurs

Two of the most common methods for the industrial processing of pozzolans are via suspension calciner (also known as a flash calciner), or via rotary kiln. FCT has developed versions of each of these technologies in the form of FlashCalxTM and RotaCalxTM, based on our team’s extensive experience working with calcined clay technologies for more than four decades. Having these two products in its portfolio, FCT is an unbiased partner to find the best solution in each specific project, to each specific client, each specific set of constraints and especially with each specific type of clay.

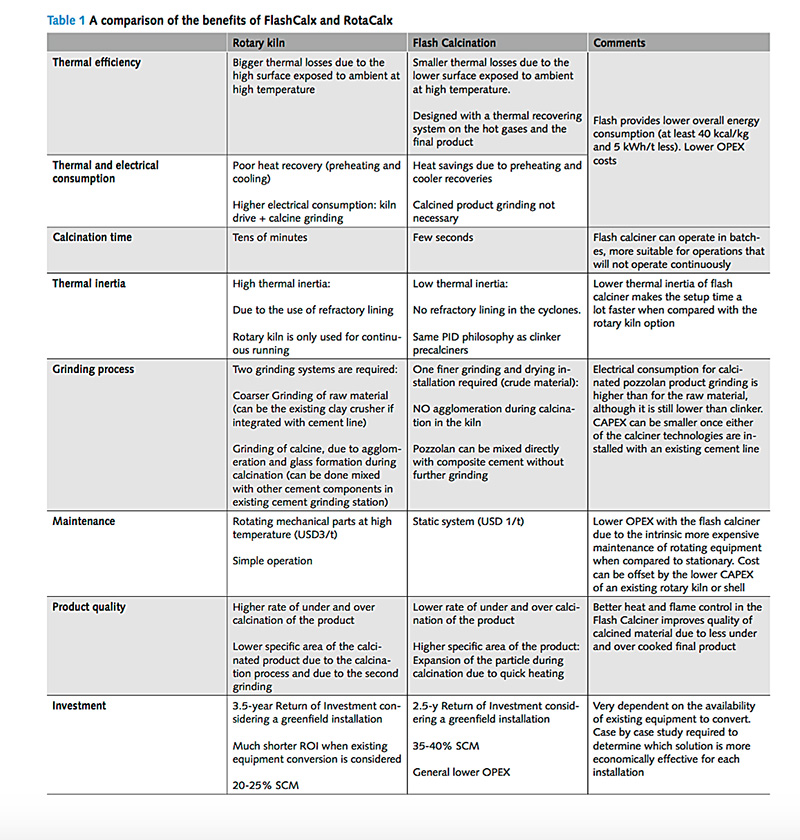

The heating process that the clay is submitted to in both technologies is similar, however each method has its own particularities, advantages, and disadvantages. Trade-off studies should be conducted, and individual projects evaluated with their own specifics and particular costs, to find the best solution on a case-by-case basis.

A key factor for consideration is the characterisation of the clay. For example, flash calcination is usually preferred for clays with a very small and precise calcination temperature window. However, for clays with very hard particles, a rotary kiln would be the better option due to the longer residence time.

Other important factors for consideration include the intended processing amount, whether the plant is greenfield or brownfield, whether there is a call to integrate or repurpose existing equipment, available footprint, the fuel type(s) to be used, and the available budget.

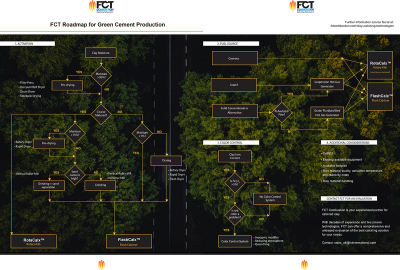

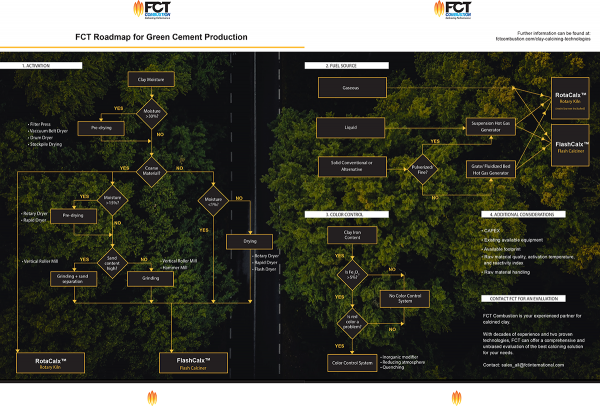

Figure 3 demonstrates the different factors that could influence selection when evaluating the best method for processing SCM. To download the map in full size, please visit here

Various factors can influence whether flash calcining or rotary calcining is the most suitable solution for a given material.

FCT has developed FlashCalx™ technology, a flash calciner for the thermal treatment of clay which results in a highly reactive pozzolan for green cement. Generally, the use of a flash calciner is acknowledged to be the ideal solution for greenfield plants as opposed to a rotary kiln, as in most cases, the flash calciner solution can offer faster return of investment.

Characterised by quick start, easy operation, and a small footprint, FlashCalx™ is available in various sizes with either a separate line or inline calciner depending on the client’s needs. The system allows for hot gases to be recycled at various points, resulting in reduced fuel and heat consumption. An increase in up to 20 on strength development has also been reported when the flash calciner based SCM is used as part of a blended cement.

Before it can be fed into the FlashCalxTM, the clay must be a dry, fine powder. To achieve this, the raw material must be dried down to 1% moisture through either a flash dryer, rotary dryer, or similar, depending on the moisture content, electric energy consumption, footprint, and other factors.

Although clays are by nature a fine material, a dryer-grinder may instead be necessary and should be carefully selected based on the moisture and composition of the material. The installation of a grinder can also provide other benefits, including the ability to remove inert material such as sand removal prior to injection into the flash calciner, which would reduce specific thermal energy requirements and maintenance.

FCT’s FlashCalx™ technology is a suspension calciner for the thermal treatment of clay

In the beginning of the process, the first two cyclones on the top of the tower are used for heating the calcined clay. A bucket elevator is used to feed the fine clay to the top of the tower. The elevator can also be used to create the recirculation of clay in the tower, especially during the preheating process, thereby virtually eliminating off-spec material.

After the material is fed into the flash calciner, the target is to increase the temperature of the clay to the required calcination temperature which is material specific. Heat transfer is achieved through intimate contact between the hot gases and the fine clay particles, creating improved heat recuperation for the system when compared to a rotary kiln. An induced draft process fan controls the transport in the preheat/calcination sections, while a baghouse filter is applied for dedusting. The gases coming out from the flash calciner installation can then be reutilised to dry and grind the raw clay, further decreasing thermal consumption.

An innovative hot gas generator provides extreme fuel flexibility for the client to use the most readily available, preferred, or cost-effective fuels. The hot gas generator fires not only traditional fuels such as natural gas, fuel oil and pulverised fuel, but also solid fuels without need for grinding, including lumpy coal/petcoke and alternative fuels such as biomass and RDF/SRF.

The installation of a state-of-the-art hot gas generator provides extreme fuel flexibility

Dihydroxylation of the clay is achieved between the calciner riser and calciner cyclone. The reaction temperature is easily controlled by a temperature-fuel PID loop, normally ranging from 600°C to 900°C depending on the characteristics of the clay. As mentioned, the ability to control the temperature within a narrow window is key, especially for more temperamental clays such as montmorillonite, so that recrystallisation does not occur.

Refractory is only applied in the combustion chamber, riser and calciner cyclone, which makes heating faster, less expensive and provides the ability to re-start the system from cold condition within 1-2 hours. Through FlashCalxTM all material is transported either through pneumatic conveying or gravity, translating to a low maintenance, low weight, and high reliability installation.

Once the reaction is complete, the product arrives at a set of cooling cyclones which are responsible for decreasing the calcine temperature while recovering heat to both the hot gas generator and raw meal drying. Gas flow in the cooling section is controlled by another process fan, which allows for separate control between the preheating/calcination section and the cooling section of the calciner, adding more flexibility to the system.

Finally, the product is pneumatically or mechanically conveyed to the product silos or directly to the finish mill separator to be blended with cement. As FlashCalxTM easily controls and prevents the melting and agglomeration of the clay, the calcine has a high specific surface area, which leads to a highly reactive pozzolan with none or minimal requirement for finish grinding.

RotaCalxTM is FCT’s rotary kiln solution for clay calcining, suitable for both greenfield plants as well as brownfield projects where a kiln may have been mothballed previously and some equipment still exists.

Clinker rotary kilns can be effectively repurposed for clay calcining application, and FCT engineers have extensive experience with this dating back to the 1980’s. Existing parts of kilns or dryers can be matched and integrated with new equipment to complete the design and supply with reduced capital costs.

Although homogenous granulometry is required to achieve homogenous calcination, rotary calcining allows for a coarser feed material to be utilised due to longer residence time in the kiln. For clays with higher moisture content RotaCalxTM allows operators to directly feed the material to the back of the kiln. This can result in reduced costs associated with pre-processing, since there is no need for grinding and drying of the material prior to injection in the kiln.

A wide range of fuels can be used, and multiple fuel types can be fired simultaneously. Rotary calcining can also be a desirable option for operators who wish to use fuels that are lighter in weight, such as fluff or sawdust, that may be less suited to use in hot gas generators installed as part of a flash calcining plant.

Table 1 provides a comparison of the two discussed calcined clay technologies.

In the past, a key challenge to commercialisation of green cement has been the ability to keep the traditional cement grey colouring, as the iron (Fe) content often found in clay can result in the product being a reddish hue depending on how it combines to oxygen (O).

Although the colour of the cement does not correlate with any issue of quality, it can have an influence on the end-user’s perception and ultimately be rejected in some cases. Different strategies exist to negate this issue, and each has its own advantages and disadvantages.

FCT has a proprietary solution to maintain the traditional ‘cement grey’ colour, regardless of iron content in the clay

Iron compounds in the form of hematite (Fe2O3) have a reddish hue and when in the form of magnetite (Fe3O4) have a dark-greyish hue. At higher temperatures, the iron is mostly in the form of magnetite. Therefore, it is important to keep the iron in magnetite form during the cooling of the clay after calcination, somewhat like what is required in white clinker manufacturing, to allow the traditional grey colour (or white, in case of white clinker) to be maintained.

One strategy is oxygen depletion, where oxygen is minimised in the kiln operation. This can be achieved by either operating in close to a reducing condition (e.g., in the back of the kiln where the oxygen monitor can be set at less than 1%), or by fuel injection close to the kiln discharge, or in the cooler or injecting fuel mixed directly with the raw clay. However, the associated secondary fuel source for colour control will require additional control and more equipment. Mixing fuel to the clay input to the calciner can also generate problems with volatile organic compounds and other hazardous emissions as those constituents do not spend the necessary time at necessary temperature for their destruction.

Another strategy is quenching, where magnetite is stabilized from high temperatures down to approximately 350°C, so that it stays in its form. This can be achieved through water spraying, or by direct cooling in an inert environment, though this results in higher heat consumption as heat is not recuperated. Energy is also required for the water spray action and, as more gases are exhausted to extract the water, the installation becomes less efficient so an investment in larger equipment would be required, resulting in increased thermal and electrical energy consumption.

FCT has developed an innovative alternative, through the addition of inorganic modifiers to achieve the traditional grey hue without impacting on fuel consumption or having a negative impact on emissions. Depending on the structure and mineralogy of the clay, instances where the method has resulted in additional side benefits, including increased strength, have been reported. Although an increase in temperature is required, the inorganic modifiers are inexpensive, there is limited handling involved compared to some other strategies, and the additional heat can be recovered.

With a specialist team who have successfully commissioned tens of calcined clay plants around the world, FCT is well placed to provide specialist advice to customers to ensure smooth adoption of their chosen production method.

To ensure quality expectations are met, FCT collaborates with associated laboratories to perform Thermogravimetric/Differential Scanning Calorimeter and Reactivity tests, among others. These are performed at the very beginning of any clay calcination project evaluation to check which kind of technology and auxiliary equipment are required. FCT will review these analysis and tailor a solution to suit the specific requirements.

Access to pilot plants in Europe, and in the Americas, are available for testing, while industrial scale tests can also be performed in a 10 tph unit. The calcined clay can be returned to the client to allow plant scale tests in the cement milling circuit for final proof of quality before building a full plant.

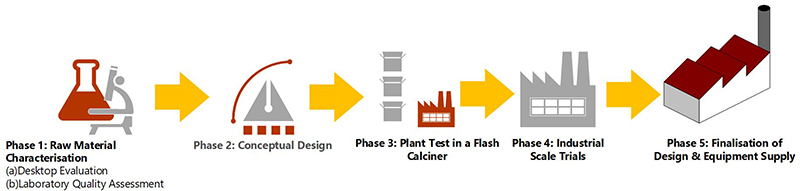

The process, from initial evaluations to design and supply, is as follows:

FCT has developed a process to ensure best outcomes for the customer

Phase 1: Raw material characterization – reactivity, colour, activation temperature, moisture, iron, sand, fineness and other factors are studied

Phase2: Conceptual design – a conceptual design of the calcination plant is made, including the main equipment selection based on the results of Phase 1.

Phase3: Pilot plant tests and trial LC3 cement testing

Phase4: plant scale production of calcined clay and bulk cement plant trials

Phase5: Design and supply, commissioning, and support of clay calciner

For more information about clay calcining, including a downloadable equipment selection diagram and other materials, please click here

For more information, please contact our specialist Clay Calcining Team by clicking here and we would be happy to discuss your specific needs. Alternatively, we also have a wealth of information on our YouTube page about clay calcining and other topics, which you may find useful.