For over 30 years, FCT has expertly solved

the most complex combustion and kiln issues

around the world.

Profit from outstanding process performance delivered by the combustion experts. Comprehensive burner services with the expertise needed to identify and solve problems, keep your kilns operating, and maximize your output and profitability.

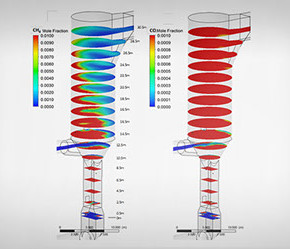

CFD modeling

FCT’s proprietary CFD flame and heat transfer modeling expertise and experience is applied to solve real problems in high temperature processing industries.

Whether it is incomplete combustion, refractory failures, product quality and production issues or emission pressures, FCT’s modeling capability can help determine the cause and the solution.

Used by FCT since 1990, it is also used for optimization of burner and combustion systems, and R&D for development of new burner designs and combustion chamber optimization.

Burner upgrades

FCT can modify existing burners with minimal capital outlay to improve performance. We can assess your burner design, operating requirements, design and fabricate the necessary modifications.

Spares and after sales service

We provide a complete range of high quality spares for our equipment.

Our global network of offices are available to provide prompt after-sales service to support your operations.

Site services

FCT’s experienced engineers provide efficient supervision of site services including:

- Installation and commissioning

- Inspection of burners during shutdowns, identifying issues and carrying out necessary repairs

- Monitoring of combustion efficiency during operation and over time

- Training engineers, operators and maintenance staff

- Benchmarking against industry best practice.

Process auditing

Our experienced engineers can help assess the status of your plant. We can:

- Audit plant efficiency, particularly combustion efficiency against benchmarks

- Audit plant emissions performance against compliance and best practice

- Carry out safety audits of installed combustion equipment for compliance

- Audit plant procedures such as start up and shut down for safe practices

- Identify improvements possible.

Engineering services

Our process and design engineers can help optimize your operations. We can provide engineering assistance including:

- Functional safety including HAZOPs and SIL assignments

- Plant design modifications to calciners, ducts and kiln hoods

- Plant optimization and de-bottlenecking

- Alternative fuel system design

- Semi-direct and semi-indirect coal conversions.